The first step in an Odyssey of Orthopaedic Footwear Technology.

Orthopedic footwear technology revolutionizes foot health, combining high-tech material advancements with innovative design. This article will explore the materials, design methodologies, and manufacturing processes adopted within orthopedic footwear capabilities for comfort and support. As we unfold, we see how such enhancements ring in functionality and comfort in orthopedic footwear, opening up the road for a future of healthier, happier feet.

Orthopedic Insoles: Providing Comfort and Support to the Feet

Orthopedic insoles, also known as orthotic inserts, are considered a great way to have one’s foot posture engineered intricately for equal pressure distribution. They provide fantastic support to one’s foot inside one’s shoes. Two kinds of these brilliant orthopedic wonders exist: over-the-counter and custom-made ones.

Over-the-Counter Orthopedic Insoles

Over-the-counter orthopedic insoles are available at pharmacies and retail outlets. They are convenient for people who need them in their pursuit of comfort and support. Prefabricated insoles are manufactured to general requirements for foot problems, such as arch support, cushioning, and stability.

Off-the-shelf insoles are less accurate than custom-made ones but are cheaper and easier to use for the average person. They relieve minor to moderate pain from foot problems and are, as such, pretty popular for anyone who wants to increase the comfort level of everyday, common shoes.

Custom-Made Orthopedic Insoles

Custom orthopedic insoles represent the pinnacle of tailor-made footwear solutions, handcrafted to the last detail. Skilled artisans fabricate each custom orthotic to exacting specifications, individually designed to address your particular foot structure, gait pattern, and specific complaints. This will ensure total comfort and support and is highly indicated in patients with difficult-to-treat conditions or for those who require the ultimate in orthopedic care.

A podiatrist or an orthopedic surgeon usually prescribes custom orthopedic insoles. The surgeon examines the foot’s biomechanics and makes an exact mould. Manufacturers create from that mould, insoles from that mould to provide specific support, relieve pressure points, and correctly align the foot.

While these bespoke insoles might be more costly and take a bit more time to make, they often pay dividends in greatly increased comfort and long-term benefits for the feet.

Whether through the convenience of ready-to-wear options or the precision of tailor-made solutions, insoles deliver all-around support to enhance overall well-being. Achieving exceptional levels of support relies on superior materials and modern technologies, each contributing to the effectiveness of orthopedic footwear. The succeeding section examines the various materials that create cushion, durability, structure, and progressive technologies that allow accurate personalization.

Materials:

- EVA (Ethylene Vinyl Acetate) is a thermoplastic, lightweight, flexible material used primarily for cushioning.

- Polyurethane: Durable and offers good shock absorption.

- Memory Foam: Molds to the foot’s shape for personalized support.

- Gel: Reduces impact on joints and provides cushioning.

- Carbon Fiber: Offers rigidity and support while being ultra-lightweight.

Technology:

- 3D Scanning: To get an exact model of the foot.

- CAD/CAM Systems: Computer-aided design and manufacturing for accurate customized insoles.

- Pressure Mapping: Exhibits the area of high pressure so that specific areas can be targeted for support.

Custom Orthopedic Footwear Technology: Precision Craftsmanship for Optimal Comfort and Support

Orthopedic custom footwear has allowed for more personalized solutions to more problematic foot conditions and unparalleled comfort. This footwear is designed with painstaking care, as it is made to fit your foot shape, gait, and explicit needs from the orthopedic perspective. Over-the-counter options cannot match our unique support and comfort.

Technology of Custom Orthopaedic Footwear:

Custom orthopedics involves an overall assessment that a podiatrist or orthopedic surgeon must perform. They would critically examine your foot biomechanics, including the aspects of arch height, pronation, supination, and pathological conditions or deformities of the foot. Such critical analysis creates an exact mould or digital scan of the feet, laying the foundation for making custom shoes.

Customized to Perfection using Orthopaedic Footwear Technology

The main advantage is that this custom orthopedic footwear is made with precision that no other orthotics can give. We make the shoes precisely to the contours of your foot, fitting them with a glove. It is a made-to-order approach based on the shape and particular needs of your foot, including orthotic insoles, discrepancies in leg length, or extra cushioning in problem areas.

Tapping into Orthopedic Footwear Technology for Precise Support and Pain Relief

Custom orthopedic shoes are much more than comfort. They are specific in supportive and pain-relieving functions. Such a shoe would help eliminate the pain associated with plantar fasciitis, bunions, arthritis, and ulcers of the diabetic foot, which can enormously reduce pain and discomfort by offering proper distribution and alignment to improve the quality of life.

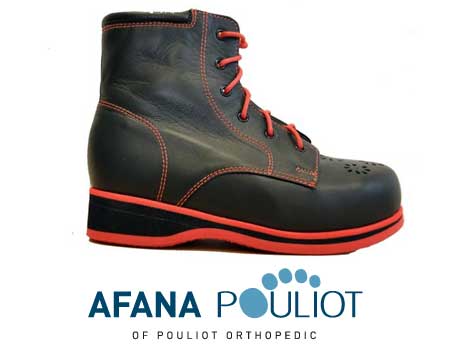

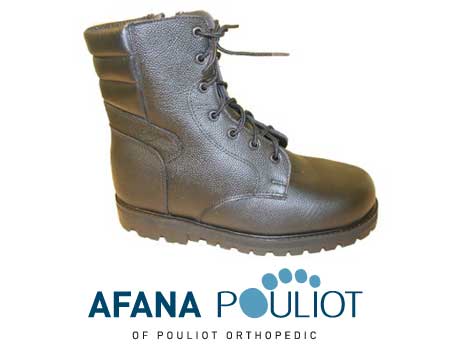

Quality Materials and Craftsmanship

The team selects only top-grade materials for bespoke orthopedic shoes. They choose high-end leathers for uppers, breathable fabrics, and carefully engineered midsoles, all designed for durability, breathability, and performance. Each pair achieves excellence, fulfilling its therapeutic purpose while showcasing skilled craftsmanship and style.

Let’s hone in below on the description of materials and technologies that go into custom orthopedic footwear and indicate how each element can add up to lasting comfort and support:

Materials:

- Leather: Breathable and moulds to the foot’s shape.

- Synthetic Fabrics: Manufacturers commonly use these materials for their lightweight and durability.

- Rubber Soles: for grip and shock absorption.

- Thermoplastic: is used in shoes for reinforcement to give extra support.

Technology:

- Biomechanical Analysis: The study of individual gaits to develop shoes to provide maximum support.

- Custom Last Making: A model of the foot for a perfect fit in shoes. Stitching Techniques Advanced: Ensures durability and flexibility.

- Advanced Stitching Techniques: Ensures durability and flexibility.

Comparison of Orthopedic Footwear Technology

While orthopedic insoles and custom-made shoes enhance foot health, they cater to different needs and support levels.

Orthopedic Insoles:

Insoles are versatile and cheap for persons with light to moderate foot discomfort. Insoles offer flexible support, easily transferring between different pairs of shoes without a significant investment. Their portability makes them a practical starting point for anyone with minor issues, as they target specific areas of discomfort or pressure within the shoe. They also work well for adding comfort to everyday wear or addressing minor alignment issues where a customized fit isn’t necessary.

Custom-Made Shoes:

In contrast, custom-made orthopedic shoes provide a comprehensive solution carefully designed to meet the needs of individuals with specific medical conditions, such as severe deformities or chronic foot pain that standard insoles may not adequately support. These shoes help the whole foot structure, including unique contours, alignment, and biomechanics. Many have the insight of a doctor or other medical professional. Custom shoes offer superior comfort, stability, and relief from complicated foot conditions; thus, the boots invest in long-term health regarding the feet and well-being.

| Feature | Orthopedic Insoles | Custom-Made Shoes |

| Purpose | Address mild to moderate foot discomfort | Provide support for specific medical conditions and severe deformities |

| Flexibility | Can be transferred between different shoes | Tailored to one pair; not interchangeable |

| Level of Support | Targeted support in specific areas | Full structural support for the entire foot |

| Cost | Cost-effective and affordable option | Higher investment for long-term foot health and specialized needs |

| Customization | General or semi-custom fit | Fully customized to the unique shape and needs of the individual’s foot |

| Ideal For | Individuals with mild discomfort or alignment issues | Those with chronic pain, deformities, or specific medical conditions |

| Maintenance | Easy to replace as needed | Durable, long-lasting solution |

| Longevity | Short to medium-term relief | Long-term, comprehensive support |

Custom Orthopedic Footwear Technology Conclusion: For the Good of the Feet

Thus, while technological advancement and evolution have occurred with the use of newer materials, orthopaedic footwear has become more functional for foot health and comfort. Orthopedically corrected insoles and individually customized shoes have odd advantages and benefits in supporting well-being.

Ready-made or bespoke orthopedic insoles provide immediate relief and specific support for every ailment that may affect one’s foot. Thus, orthopedic insoles are a very accessible introduction to orthopedic footwear, increasing comfort and lessening discomfort for many.

Conversely, it speaks to personal care with an orthopedic shoe very personally. The team crafts each model with careful attention to meet specific needs for comfort, support, and relief. It fosters long-term foot health and caters to complex conditions for enduring well-being.

Please approach Afana Pouliot for professional advice and treatment regarding personalized orthopedic footwear. Our specialists will advise you on the best path toward a healthy and comfortable life. By coming forward today, you show courage and take the first step toward a better future for your feet. Your feet deserve the best, and Afana Pouliot guides you in the right direction.